Products

Our products embody our commitment to sustainable sourcing, processing and material selection. We are proud of the durable, timeless pieces we create - and our customers love. Whilst we are known for these unique bags and continue to develop new gear with this ethos in mind, our apparel range is growing with each season. As with our bags, we are committed to creating stylish, hard wearing garments and accessories to be treasured and worn for years to come.

Materials

When Sealand started, we were able to source the “waste” we needed to create our products locally. As our business, range and production has grown, sourcing high-quality reliable waste streams has become a challenge. We have been forced to look for alternative but responsible sources. However, we are constantly on the hunt for new, ever more responsible materials and are proud to partner with some industry leaders creating more sustainable textiles than have ever been offered. All of our fabric partners are held to the highest global standards of textile manufacture.

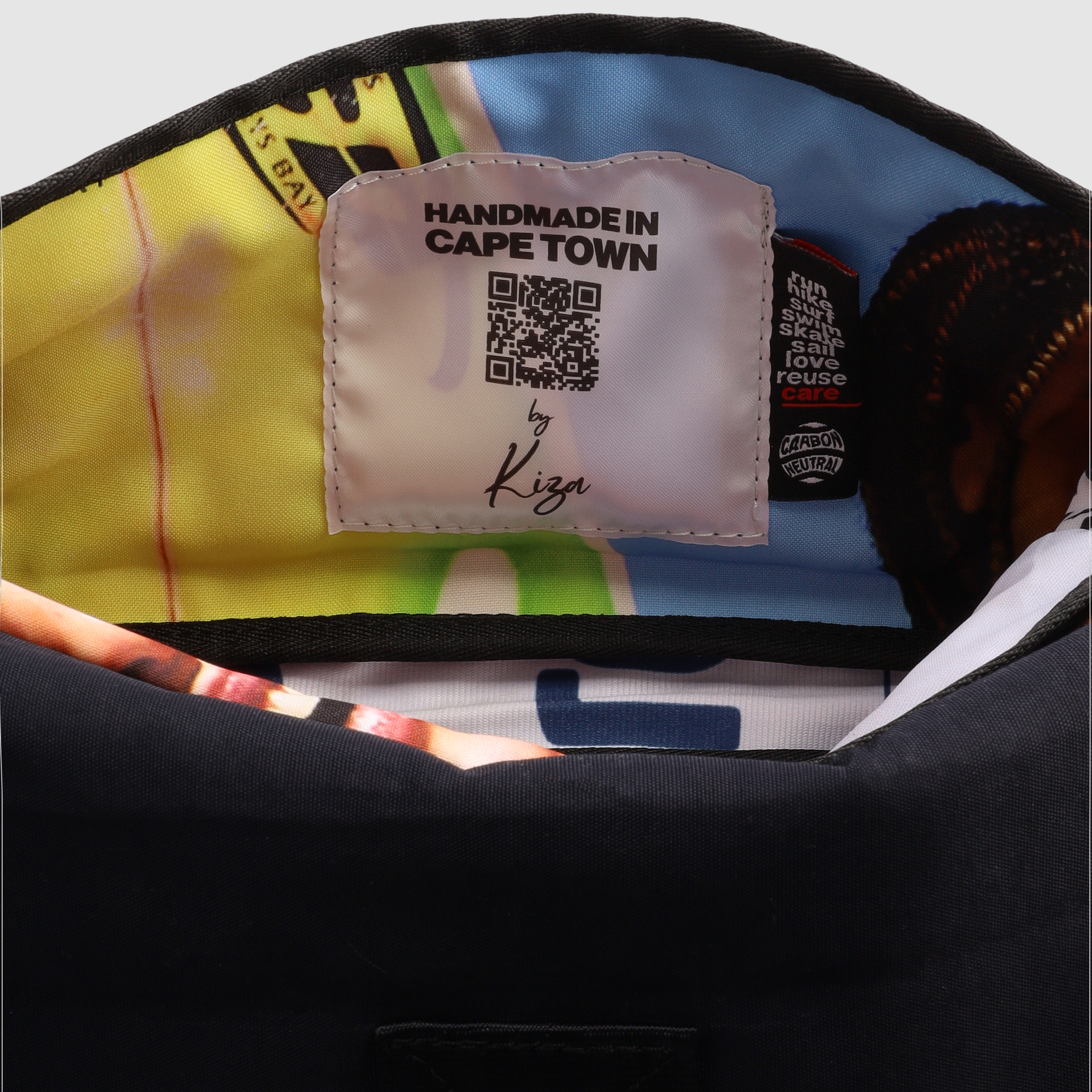

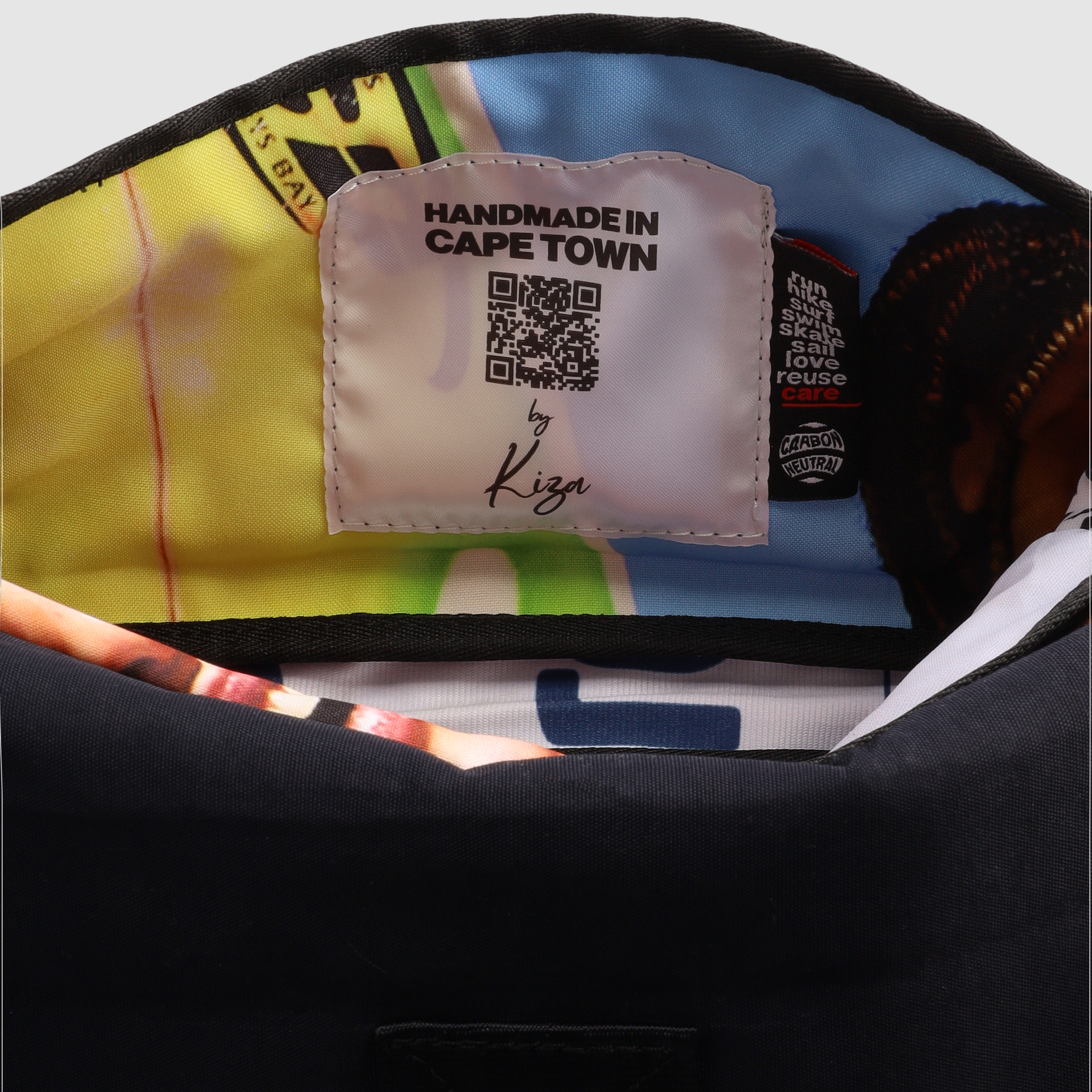

At the heart of our operations lies our Polyester Twill (Poly Twill), generously donated by our partners looking to divert their post consumer textile waste from landfill. Poly Twill is a tactile and durable material, perfect for inners. It’s commonly used as an in-store advertising material.

Each of our 100 000+ bags made since 2015 have featured a unique & vibrant Poly Twill lining, and each Sealand bag is utterly unique. Our Poly Twill is sourced from corporate partners locally, such as Pick n Pay, Ackermans, Pepkor & Mr Price. The logistics are handled by major printing partners of these businesses, Digital Express Printing and Hirt & Carter.

Yacht sail has been designed to withstand tough weather conditions, resulting in low water absorption and high durability. These factors make this upcycled material the perfect ‘ingredient’ for a lifetime warranty product such as a Sealand bag. We source from international sail manufacturers and upcycle b-grade sail material where possible.

Spinnaker and kite fabric, a brightly coloured and lighter sail material is used across many products as a flair, to add colour and vibrancy.

Earth-polluting nylon waste such as fishing nets, fabric scraps, carpet flooring and industrial plastic is transformed into ECONYL® regenerated nylon through a radical regenerative and purification process.

This regenerated nylon is then used to create brand new products that have the possibility to be infinitely recycled. We currently source this from Hoyu, a bluesign-certified manufacturer in Taiwan.

Ripstop is a versatile woven fabric which uses a special reinforcing technique to withstand tearing and ripping. Upcycled Ripstop’s durability makes this fabric the perfect base for our bags.

We source A & B-grade ripstop in South Africa, and are currently in the process of working with a supplier to develop recycled and regenerated ripstop for our bags.

Canvas is a weather resistant, easily washable fabric with the co-benefit of having mould resistant properties. Our canvas range was once all B-grade but due to sourcing requirements, we took the difficult decision to incorporate A-grade canvas into these products.

We are working with suppliers to generate locally produced recycled canvas and replace all the A-grade in our range with this, Cordura or X-Pac.

Sourced from local partner, Hemporium, hemp is a versatile, comfortable material that uses about ¼ as much water and half the land of cotton. It is also regenerative for soil.

This has been a staple within our apparel range since we first started producing, and produces comfortable, long lasting garments that are eventually biodegradable.

We utilise organic cotton in our range, which has a far lower impact than cotton farmed with pesticides and herbicides on both chemical pollution and water scarcity impact measures.

We work with local suppliers to ensure we get reliable, quality cotton processed in responsible mills. Cotton can biodegrade at its end of use and, as a natural fibre, releases none of the microplastics that fossil-fuel based fabrics may.

At the heart of our operations lies our Polyester Twill (Poly Twill), generously donated by our partners looking to divert their post consumer textile waste from landfill. Poly Twill is a tactile and durable material, perfect for inners. It’s commonly used as an in-store advertising material.

Each of our 100 000+ bags made since 2015 have featured a unique & vibrant Poly Twill lining, and each Sealand bag is utterly unique. Our Poly Twill is sourced from corporate partners locally, such as Pick n Pay, Ackermans, Pepkor & Mr Price. The logistics are handled by major printing partners of these businesses, Digital Express Printing and Hirt & Carter.

Yacht sail has been designed to withstand tough weather conditions, resulting in low water absorption and high durability. These factors make this upcycled material the perfect ‘ingredient’ for a lifetime warranty product such as a Sealand bag. We source from international sail manufacturers and upcycle b-grade sail material where possible.

Spinnaker and kite fabric, a brightly coloured and lighter sail material is used across many products as a flair, to add colour and vibrancy.

Earth-polluting nylon waste such as fishing nets, fabric scraps, carpet flooring and industrial plastic is transformed into ECONYL® regenerated nylon through a radical regenerative and purification process.

This regenerated nylon is then used to create brand new products that have the possibility to be infinitely recycled. We currently source this from Hoyu, a bluesign-certified manufacturer in Taiwan.

Ripstop is a versatile woven fabric which uses a special reinforcing technique to withstand tearing and ripping. Upcycled Ripstop’s durability makes this fabric the perfect base for our bags.

We source A & B-grade ripstop in South Africa, and are currently in the process of working with a supplier to develop recycled and regenerated ripstop for our bags.

Canvas is a weather resistant, easily washable fabric with the co-benefit of having mould resistant properties. Our canvas range was once all B-grade but due to sourcing requirements, we took the difficult decision to incorporate A-grade canvas into these products.

We are working with suppliers to generate locally produced recycled canvas and replace all the A-grade in our range with this, Cordura or X-Pac.

Sourced from local partner, Hemporium, hemp is a versatile, comfortable material that uses about ¼ as much water and half the land of cotton. It is also regenerative for soil.

This has been a staple within our apparel range since we first started producing, and produces comfortable, long lasting garments that are eventually biodegradable.

We utilise organic cotton in our range, which has a far lower impact than cotton farmed with pesticides and herbicides on both chemical pollution and water scarcity impact measures.

We work with local suppliers to ensure we get reliable, quality cotton processed in responsible mills. Cotton can biodegrade at its end of use and, as a natural fibre, releases none of the microplastics that fossil-fuel based fabrics may.

Life Cycle Analysis (LCA)

One of our biggest challenges as a business has always been the acquisition of accurate, quality data we can trust. Every time we need to make a critical decision, we need numbers to inform and support our choices. Sealand has acquired LCA and carbon accounting software as of early 2024, a huge step towards getting quantifiable impact reports on a variety of metrics. These metrics are important not only to us but also to all our stakeholders.

We have partnered with Carbon Trail, a world leader in climate and impact tracking data to do deep dives into as many of our products as possible. Through the use of this software, we are now able not only to track the impact of our gear and business on a global scale, but also to simulate the effects of decisions we take today on future emissions and business.

Our philosophy extends beyond making great, responsible products – we want to empower our customers to make great, responsible choices.

This process has prompted us to seek to understand, in greater depth, the materials and processes employed by every one of our suppliers. In the future, this will be a key factor in our decision-making process. If we can quantify our impact across the board, we can tailor our product design and, in so doing, reduce our impact on the environment to the greatest degree possible.

Circularity

As the true cost of raw material extraction becomes more obvious and more transparent - and the impacts of end-of-life scenarios become quantified - Sealand has committed to exploring circularity options with greater vigour. Our inputs are largely upcycled, regenerated and recycled materials and thus circularity is already “baked in” from the start.

However, we are doing our best to ensure that we close the loop as far as possible: in terms of our Evergreen Guarantee, we commit to mending any repairable product, for free, for a period of 10 years from sale.

Our Manifesto

We use waste where we can. What is waste to others we, at Sealand, see as a valuable resource. We upcycle textile waste from various streams to reduce the need to landfill harmful and polluting material, whilst breathing new life into usable, vibrant fabric.

We source responsible, recycled materials. If our local waste streams are depleted and we are compelled to incorporate other materials, we avoid virgin fabrics as much as possible. Instead, we look for innovative, durable alternatives such as regenerated and recycled materials. Our apparel is created with durable natural or recycled fibres, made to last and remain timeless through changing trends.

We innovate both locally and globally. Where locally sourced sustainable materials are not available, or local manufacturing technology is not yet appropriately advanced, we work with like-minded partners committed to the highest of sustainability standards. In conjunction with these aligned suppliers, both local and international, we have actively developed new, responsibly produced alternatives to conventional fibres and fabrics. Our ultimate aim is to bring these innovations to South Africa and localise our value chain as much as possible.

We move gently through the world. When we do need to move our products, we do in-depth analysis of the methods and efficiencies of our various routes and aim to minimise impact wherever possible. We partner with low-impact delivery and packaging companies and seek to keep our production local whenever possible. If, currently, the most sustainable option exists only overseas, we use shipping as a low-carbon alternative to air freight, and work to onshore these technologies and production.

We deliver value for all. We respect our customers, employees, stakeholders, partners - and planet. Sealand tries hard to ensure that the value chain involved in creating our gear delivers benefits for every player, that fair wages are paid for fair work, exploitative practices are eliminated and our environment is respected from source to sale.

We close the loop. Sealand strives to break free from the linear economy model of extraction, use and discarding of resources. We leverage industrial symbioses to incorporate external waste streams into our production, we aim to keep our products in use for as long as possible through repairs and we reuse and recycle 100% of our production waste, incorporating these offcuts into local sewing projects and special in-house initiatives.

We are holistic. Everything we do, create or support has an impact, positive or negative, on our world. We aim to tailor these impacts, in as much as possible, to the environment they affect. Our material areas of concern are reduction of GHG emissions, water use, waste production and energy consumption, and increases in employee wellbeing and positive social impact. We select feedstocks, materials, processes and suppliers in accordance with local environmental capacity and concerns. In water scarce areas, we reduce water consumption. In areas with risk of forced labour, we increase accountability and wellbeing. In areas with fossil-fuel based grids we reduce energy consumption. And at every turn we work with partners to reduce carbon and GHG emissions.

Ensuring that our operations are sustainable and beneficial to all stakeholders is a complex, multi-faceted task with many challenges but many rewards - for all. We endeavour to be as responsible, as transparent, as sustainable and as progressive as possible, and work only with those aligned to the same mission. Together, we make our planet better.